Updates!

So, things I have accomplished:

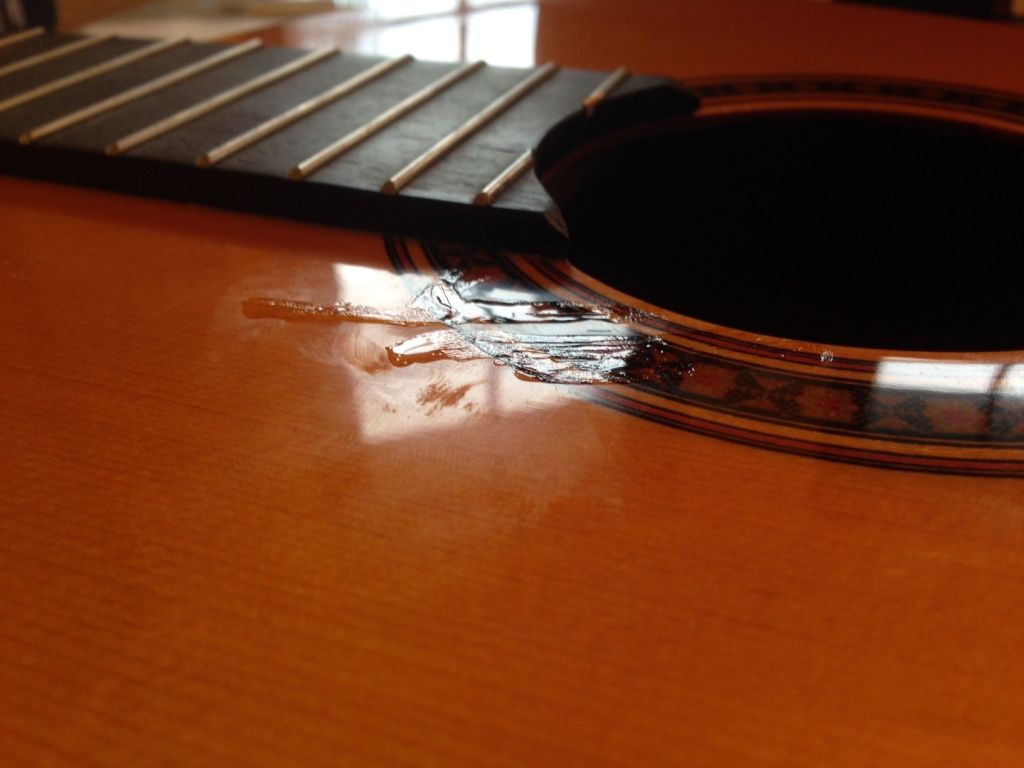

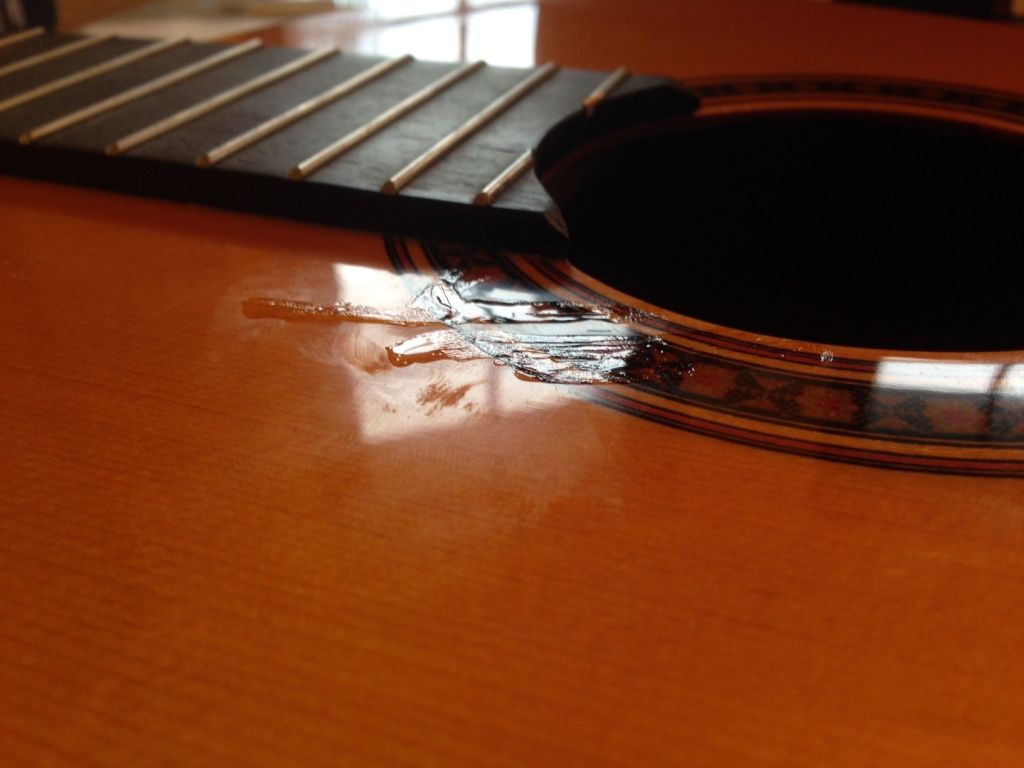

1. Gluing the brace back to the top, and then gluing the crack in the brace. I gave the glue 24 hours between each step. As you can see, I got a bit gloppy with the glue while I was repairing the crack. I will probably try to clean up the worst of the excess glue blobs, but I don't anticipate spending a lot of time on it. I did it, I learned from it, and I'll be more careful if there's a next time.

In other news, the craft stick braces worked great, but they definitely have a limited life. It's difficult to cut the notches without starting a lengthwise split in the grain, and then when you wedge them into place, the pressure makes them want to split even more. I made 3 really good ones, and they lasted for the 2 repairs, but by the time I removed them the second time, only 1 of them was still reusable. Fortunately they are cheap and easy to make.

Despite possibly using too little glue on the first half of the repair, and too much glue on the second half, everything feels solid. Hopefully it'll stay together when it's strung up to full tension.

2. I also fixed the little damaged piece around the soundhole (3rd pic in the 1st post). No pics of the repair, but I basically just used a toothpick to dab a bit of glue underneath the separated piece, and then clamped it shut with a small Irwin Quick Grip and two small pieces from a craft stick to protect the wood. Came out great.

3. I decided that if this was going to be an educational project, I may as well attempt to repair the cracks in the poly finish as well. I got some clear liquid CA glue, and dabbed it over the cracked area with a toothpick. It looks pretty bad now, but I figured since I'll be wet-sanding and polishing the area down flat, it would be better to make sure every crack was completely filled. I will probably use a taped-up razor blade to scrape down the high spots before I start sanding.

Any thoughts on how long I should allow the CA glue to harden before attempting to scrape or sand it down? I have plenty of time -- my sandpaper and Micromesh probably won't arrive for 2 or 3 days.

4. In between the other steps above (read: while waiting for glue to dry), I also sanded down a compensated Tusq saddle to replace the plastic Yamaha saddle. The plastic saddle was quite high and also pretty loose in the bridge. I got the Tusq saddle to slide smoothly into the bridge with just a hint of snugness, and brought it down about a millimeter lower than the Yamaha. I have some bone saddles on the way, so if the Tusq saddle ends up being too low, or I don't like the tone, I'll start over with a new one. No pics.