New to the site and new to guitar building and wood working in general. I have not really done any woodworking since I was a freshman in high school, and thats been a few years now

The updates as well will probably be few and far between. I am not exactly set up to do any wood working and I really dont have any of the power tools to make my life easier nor the budget to go out and buy everything. So I will have to get the necessities as I need them and try and make do on some steps without luxuries.

My goals for this build is to end up with the same amount of eyes and fingers/limbs as I started with and end up with a body that is useable. I am by no means expecting anything close to perfection, I am looking forward to playing something that I built whether its pretty or butt ugly. I am not going to try and tackle a neck, maybe next time. Babysteps!

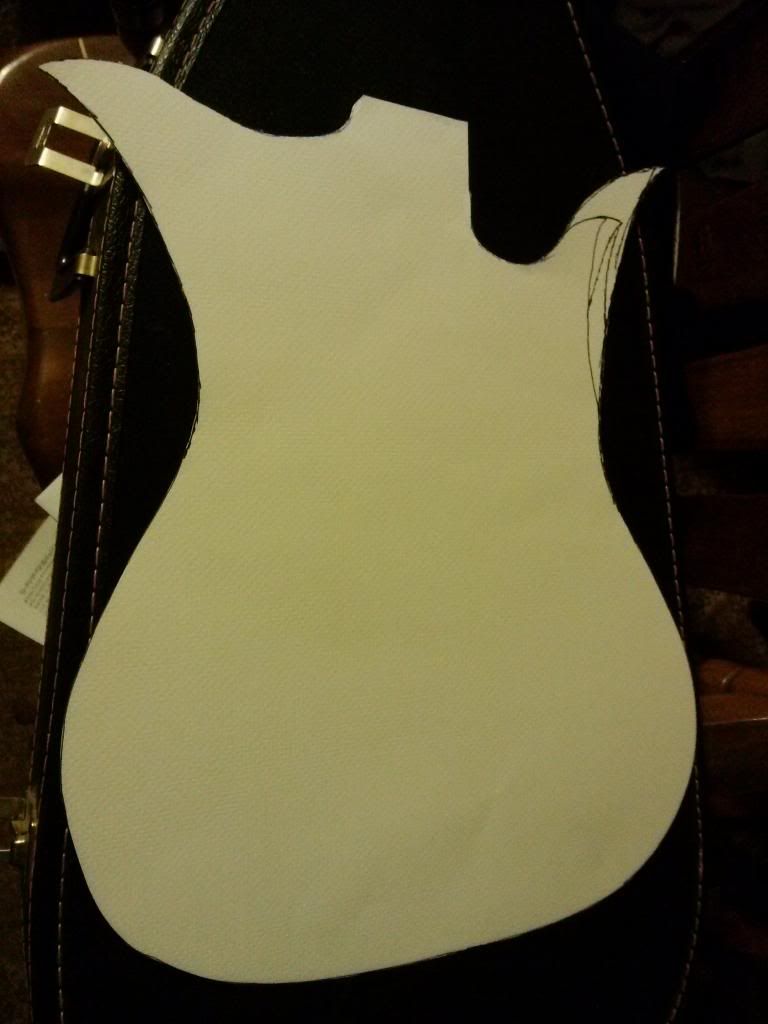

I am finally done rambling and onto my build. My build is inspired by the old Teisco Del Ray Tulip guitars of the 60s/70s. For my template, I guess you can call it, I took my old Jedson/Teisco and made an outline of the guitar, I then doodled around with the horns until I found something I liked, and then lined up a strat with the neck to make the cutaways more player friendly. I ended up with this. I am pretty pleased with it, and actually the end body will have a flat area on the bottom for two reasons 1. My Cap wood wasnt wide enough and 2. since my cap wood wasnt wide enough I will put the jack down there so it will look like it was on purpose

I got to the lumberyard yesterday, and ended up with some .25" Black Walnut and a 1.25" Soft Maple Slab. Its definitely not going to be a light body by any means

I then had to find my workbench aka the metal cabinet, after the baby was born the mudroom became a catch all

I found an arrangement for the Black Walnut that looked alright. It had straight edges so I didnt have to worry about using a Jointer on them, which is good because I don't have one and I didnt think about having the guy at the mill do it

The Gorilla Glue claims a 20 minute clamp time, I gave it about an hour and then carefully unclamped it and glued on the Maple slab. I wish I bought more then 6 clamps now, I am a bit worried I didnt get enough pressure. More clamps will be on the list for the next time I head to the big box lumber yard that way I got them for the next build. I also didnt have really any wood blocks around for the clamps to sit on, I used some old legs off of an old coffee table to try and help get some even pressure.

My next step will be cutting the body out. I don't have a 14" Band Saw, no access to one and definitely cant afford to go out and buy one so I will be using a Makita Jigsaw I picked up at a pawn shop for $10. I have a feeling that a Bandsaw will be my first major power tool purchase. I am hoping I will be able to do it before I have to leave for work tomorrow, if I dont have a chance to, it will have to wait till next Saturday. I would like to have mama to be home with the baby when I do it, I am sure it will be noisy.

Like I said before, comments, suggestions, tips, tricks, everything is welcome. I would prefer to do it right the first time since its pretty hard to turn sawdust back into wood

Thanks for looking!