Dedicated table saw for fret slots.

- John Kingma

- Posts: 213

- Joined: Mon Jan 09, 2012 7:22 am

- Location: N 44° 59.564 ~ W 079° 35.317

- Contact:

Dedicated table saw for fret slots.

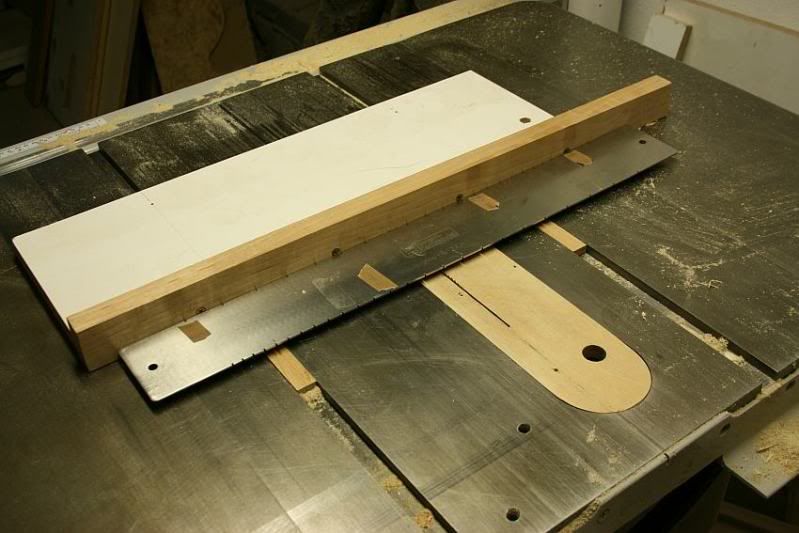

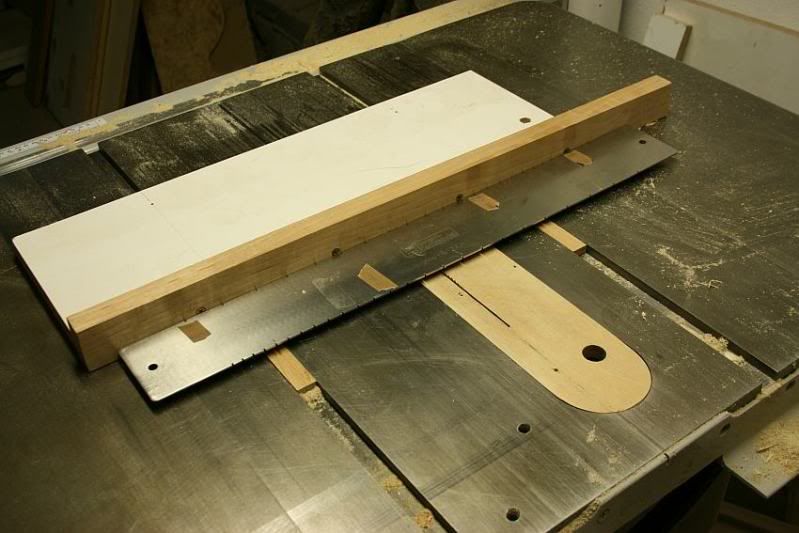

I found a small Delta table saw last week (mounted to a workmate) for $45.00 and set it up as a dedicated saw for cutting fret slots. When I'm not using it I can just fold up the workmate and slide it under my main work bench.

John Kingma,

Builder of Fine Sawdust & Expensive Kindling

Builder of Fine Sawdust & Expensive Kindling

- John Kingma

- Posts: 213

- Joined: Mon Jan 09, 2012 7:22 am

- Location: N 44° 59.564 ~ W 079° 35.317

- Contact:

Re: Dedicated table saw for fret slots.

I built a sled out of some oak scraps so that I can use a Stew-Mac fret slotting guide and blade with it. Once I built the sled and set it up, I cut all the slots for a fretboard in a matter of minutes. Sure beats doing it by hand. I wish I had done this years ago.

John Kingma,

Builder of Fine Sawdust & Expensive Kindling

Builder of Fine Sawdust & Expensive Kindling

-

Mario Proulx

- Posts: 821

- Joined: Fri Jan 06, 2012 12:08 pm

Re: Dedicated table saw for fret slots.

Does the arbor run perfectly true(no wobble) and perfectly perpendicular to the table's slots, and without any side-to-side play(slack/slop...)? I ask because I had dedicated an older table saw to fret slotting at one time, only to find it was far from ideal, and wasn't worth the 1 minute(max) it takes to swap the blade on the Unisaw... Fret slotting is the most precise cuts we make on any part the instrument; may as well make sure the saw used is a fine one, and well tuned.

- John Kingma

- Posts: 213

- Joined: Mon Jan 09, 2012 7:22 am

- Location: N 44° 59.564 ~ W 079° 35.317

- Contact:

Re: Dedicated table saw for fret slots.

I don't have any real easy way to check "accurately" for runout, but it operates smoothly and there is no blade/arbour wobble that I can feel during use. The slots cut very smoothly and accurate... I'm happy and fairly impressed with what my $45.00 got me.

John Kingma,

Builder of Fine Sawdust & Expensive Kindling

Builder of Fine Sawdust & Expensive Kindling

-

Gordon Bellerose

- Posts: 1186

- Joined: Wed May 30, 2012 11:47 pm

- Location: Edmonton AB. Canada

Re: Dedicated table saw for fret slots.

I'm more interested in your jig. Any chance you could give me your plan? I'm pretty sure I could figure it out, but maybe you made a mistake that I could avoid.

I need your help. I can't possibly make all the mistakes myself!

- John Kingma

- Posts: 213

- Joined: Mon Jan 09, 2012 7:22 am

- Location: N 44° 59.564 ~ W 079° 35.317

- Contact:

Re: Dedicated table saw for fret slots.

There was no plan Gordon. I just went by the seat of my pants. Unless you are talking about the metal "fret template" part of the jig... and that came from Stew-Mac.

http://www.stewmac.com/shop/Fretting_su ... lates.html

http://www.stewmac.com/shop/Fretting_su ... lates.html

John Kingma,

Builder of Fine Sawdust & Expensive Kindling

Builder of Fine Sawdust & Expensive Kindling

Re: Dedicated table saw for fret slots.

I have this book, Care and Repair of Shop Machines: A Complete Guide to Setup, Troubleshooting, and Maintenance , which has some pretty good info on table saw alignment, among other things.

http://www.amazon.com/Care-Repair-Shop- ... 156158424X

Here's some info online that seems pretty good too. I don't have a "master plate" so I simply used a good 12" saw blade to align the arbor flange for parallelism, it seems to get me close enough. A good dial indicator is required, however

http://www.newwoodworker.com/basic/tsalign.html

As for making sled, or a sliding platform, for cutting fret slots on your table saw, Stewmac has some instructions for making one on their web site. Like John, I made mine without any real instructions, but the principle is the same

http://www.stewmac.com/freeinfo/Fretting/i-4915.html

http://www.amazon.com/Care-Repair-Shop- ... 156158424X

Here's some info online that seems pretty good too. I don't have a "master plate" so I simply used a good 12" saw blade to align the arbor flange for parallelism, it seems to get me close enough. A good dial indicator is required, however

http://www.newwoodworker.com/basic/tsalign.html

As for making sled, or a sliding platform, for cutting fret slots on your table saw, Stewmac has some instructions for making one on their web site. Like John, I made mine without any real instructions, but the principle is the same

http://www.stewmac.com/freeinfo/Fretting/i-4915.html

-

Mario Proulx

- Posts: 821

- Joined: Fri Jan 06, 2012 12:08 pm

Re: Dedicated table saw for fret slots.

Only thing I can add is that my fret slotting "jig" has two runners, to maximize accuracy. Most of my table saw jigs that make use of the miter slots have two runners, in fact. It's a bit finicky to get them perfectly parallel when building the jig, but well worth the effort.

-

Brian Dyskin

- Posts: 17

- Joined: Sat Jan 07, 2012 7:21 pm

- Location: Melbourne, Australia

- Contact:

Re: Dedicated table saw for fret slots.

I made a similar setup with a cheap table saw (less than $100 new). This particular saw doesn't have height adjustment, so I had to shim the table to get the right amount of blade showing.

The saw with the Stewmac blade installed: Underside of auxiliary table

Underside of auxiliary table  auxiliary table with shims on the saw:

auxiliary table with shims on the saw:  sled on the table - the sled has two runners which run along the edges of the auxiliary table:

sled on the table - the sled has two runners which run along the edges of the auxiliary table:  blade clearance:

blade clearance:

I used an existing fretboard double sided taped to the new board as a template and just lined up each fret with a mark on the sled rather than using a pin. Worked beautifully. narrow test board next to original "template" board

narrow test board next to original "template" board

Next time I'm just going to use a printout from wfret as the template.

(photos above are clickable thumbnails - I hope the explanation is clear - happy to answer any questions if not)

The saw with the Stewmac blade installed:

Underside of auxiliary table

Underside of auxiliary table  auxiliary table with shims on the saw:

auxiliary table with shims on the saw:  sled on the table - the sled has two runners which run along the edges of the auxiliary table:

sled on the table - the sled has two runners which run along the edges of the auxiliary table:  blade clearance:

blade clearance:

I used an existing fretboard double sided taped to the new board as a template and just lined up each fret with a mark on the sled rather than using a pin. Worked beautifully.

narrow test board next to original "template" board

narrow test board next to original "template" board

Next time I'm just going to use a printout from wfret as the template.

(photos above are clickable thumbnails - I hope the explanation is clear - happy to answer any questions if not)

- John Kingma

- Posts: 213

- Joined: Mon Jan 09, 2012 7:22 am

- Location: N 44° 59.564 ~ W 079° 35.317

- Contact:

Re: Dedicated table saw for fret slots.

Mario Proulx wrote:Only thing I can add is that my fret slotting "jig" has two runners, to maximize accuracy.

As does mine...

John Kingma,

Builder of Fine Sawdust & Expensive Kindling

Builder of Fine Sawdust & Expensive Kindling

-

Mario Proulx

- Posts: 821

- Joined: Fri Jan 06, 2012 12:08 pm

Re: Dedicated table saw for fret slots.

a template and just lined up each fret with a mark on the sled rather than using a pin. Worked beautifully

Oy! That's way too inaccurate for fret slotting, sorry! Fret slotting isn't something to do by 'eyeballing' things.

Decent intonation is tough enough to achieve with precisely placed frets, and impossible to achieve if even one fret is "off" by a few thou....

Oy! That's way too inaccurate for fret slotting, sorry! Fret slotting isn't something to do by 'eyeballing' things.

Decent intonation is tough enough to achieve with precisely placed frets, and impossible to achieve if even one fret is "off" by a few thou....

- Mark Swanson

- Posts: 1991

- Joined: Thu Jan 05, 2012 11:11 am

- Location: Grand Rapids, Michigan USA

- Contact:

Re: Dedicated table saw for fret slots.

Mine does, too.

And Brian, that is a nice saw but I strongly suggest that you install an index pin, or if you want to keep using a fingerboard as your template, then you could use a shim of .024 to index the slot. It eliminates error (which WILL eventually happen) and makes things easier and faster. I see Mario jumped and said the same thing, pretty much!

And Brian, that is a nice saw but I strongly suggest that you install an index pin, or if you want to keep using a fingerboard as your template, then you could use a shim of .024 to index the slot. It eliminates error (which WILL eventually happen) and makes things easier and faster. I see Mario jumped and said the same thing, pretty much!

- Mark Swanson, guitarist, MIMForum Staff

Re: Dedicated table saw for fret slots.

Yup, two runners and an index pin here, too. I use a Stewmac blade and templates.

-

Brian Dyskin

- Posts: 17

- Joined: Sat Jan 07, 2012 7:21 pm

- Location: Melbourne, Australia

- Contact:

Re: Dedicated table saw for fret slots.

Thanks for the advice all.

Until I did the trial, I was thinking about cutting 10mm off the edge of a fretboard and gluing it side on to a piece of ply to use as a template, then using a shim of metal in the fence of the sled as the index. Following your advices I may do that. Do you think it will make a difference which sort of timber I use for the fretboard? Will an ebony template (for example) last longer than a rosewood one?

Thanks,

Brian.

Until I did the trial, I was thinking about cutting 10mm off the edge of a fretboard and gluing it side on to a piece of ply to use as a template, then using a shim of metal in the fence of the sled as the index. Following your advices I may do that. Do you think it will make a difference which sort of timber I use for the fretboard? Will an ebony template (for example) last longer than a rosewood one?

Thanks,

Brian.

-

Mario Proulx

- Posts: 821

- Joined: Fri Jan 06, 2012 12:08 pm

Re: Dedicated table saw for fret slots.

Yes, that would be a much better plan, and yes, the ebony will outlast the rosewood.

Take the fretboard/template to the hardware store, and you'll be able to easily find something that will be a good, snug fit. Look at utility knife blades and such. keep it short(close to your fence) and it should be stiff enough to avoid any errors from flexing.

Take the fretboard/template to the hardware store, and you'll be able to easily find something that will be a good, snug fit. Look at utility knife blades and such. keep it short(close to your fence) and it should be stiff enough to avoid any errors from flexing.

-

Brian Dyskin

- Posts: 17

- Joined: Sat Jan 07, 2012 7:21 pm

- Location: Melbourne, Australia

- Contact:

Re: Dedicated table saw for fret slots.

Thanks Mario,

I haven't noticed any issues with carefully aligning the fret with the masking tape so far, but in this case I'll trust your experience over my own. Slotted ebony boards have been ordered and I'll sacrifice the a few mm off the edge of each for templates (this way I get two for one - a fret slotted template and a slotted fretboard for the cost of the fretboard - luckily the LMI boards are wider than they need to be).

I haven't noticed any issues with carefully aligning the fret with the masking tape so far, but in this case I'll trust your experience over my own. Slotted ebony boards have been ordered and I'll sacrifice the a few mm off the edge of each for templates (this way I get two for one - a fret slotted template and a slotted fretboard for the cost of the fretboard - luckily the LMI boards are wider than they need to be).

- Murray MacLeod

- Posts: 56

- Joined: Sun Jan 22, 2012 6:52 am

Re: Dedicated table saw for fret slots.

IME, the trick with two runners is to make the width of the runners less than the width of the table slots, also shallower than the depth.Mario Proulx wrote:Only thing I can add is that my fret slotting "jig" has two runners, to maximize accuracy. Most of my table saw jigs that make use of the miter slots have two runners, in fact. It's a bit finicky to get them perfectly parallel when building the jig, but well worth the effort.

Run a length of masking tape along the inside edge of each slot, shim both runners tight to the inside edge of each slot and also shim slightly above table level, run a bead of glue along each runner, and lay the plywood jig base on top. I use a 18g nailer to reinforce the joints, but you could just leave the glue to set, and insert 2 or 3 screws in each runner. You might have to give a couple of strokes with a sanding block to the inside edge of one runner to get it running smoothly, but the parallelism is guaranteed.

-

Mario Proulx

- Posts: 821

- Joined: Fri Jan 06, 2012 12:08 pm

Re: Dedicated table saw for fret slots.

I like my runners to fit tightly, to avoid any possible slop. I fit them for a snug fit to the runners, and yes, shallower than the depth. The rest I do exactly as you suggest.

On some jigs, I've used 1/2" wide runners, and placed a few round-head #6 screws along the sides, and adjust the screws for a perfect, slop-free fit. Metal on metal also provides very little friction.

On some jigs, I've used 1/2" wide runners, and placed a few round-head #6 screws along the sides, and adjust the screws for a perfect, slop-free fit. Metal on metal also provides very little friction.

-

David King

- Posts: 2690

- Joined: Sat Jan 07, 2012 10:01 pm

- Location: Portland, OR

- Contact:

Re: Dedicated table saw for fret slots.

My runners are aluminum 3/8" x 3/4" bar stock with tape added to tighten the up.

You can also buy extruded anodized aluminum runners with a width adjustment slot that look like they would work even better.

Unfortunately my TS slots are wallowed out in the center section after 40 years of mitering by the previous owner/s

You can also buy extruded anodized aluminum runners with a width adjustment slot that look like they would work even better.

Unfortunately my TS slots are wallowed out in the center section after 40 years of mitering by the previous owner/s

- Murray MacLeod

- Posts: 56

- Joined: Sun Jan 22, 2012 6:52 am

Re: Dedicated table saw for fret slots.

I can see how the aluminum runners would work for a jig with only one runner, you would just screw through the aliminum from underneath into the plywood base, but would it be feasible to make a jig with two parallel aluminum runners ? I can't visualise how it could be done, unless maybe you used superglue for the initial fix, and then screwed upwards into the plywood ...