Page 2 of 8

Re: 3 axis router build

Posted: Thu Jan 31, 2013 3:20 pm

by David King

Acme rod is available from Grainger, MSC or Enco or any specialty hardware store in your neck of the woods.

6 feet of 1/2" is $16

6 feet of 3/8" is $13.

Stainless 304 is about twice that price but might be of a slightly higher tolerance.

I don't know why McMaster would be charging so much more but their specs might be better.

I can post links if you have any trouble finding what you need.

Re: 3 axis router build

Posted: Thu Jan 31, 2013 4:40 pm

by Eric Baack

mcmaster charges a bit more for most things, but they are convenient.

I should be able to find it from grainger, we have one in town here

Re: 3 axis router build

Posted: Thu Jan 31, 2013 5:00 pm

by Eric Baack

do you have a link to the 3/8" rod on grainger? I'm not finding any acme type rod on there for that price.

Re: 3 axis router build

Posted: Thu Jan 31, 2013 6:12 pm

by Eric Baack

I guess mcmaster has 6' of 1/2-10 with single start for $14 for a 6' piece. the price I mentioned above was zinc plated

Re: 3 axis router build

Posted: Thu Jan 31, 2013 6:31 pm

by David King

Sorry about that it must have been MSC that popped up with the 3/8-16 price

Grangers 1/2-10 x 6' link is here:

http://www.grainger.com/Grainger/Thread ... Pid=search

Suddenly Enco only shows acme "leadscrew" for $99 but that's .009" per foot accurate -nice but at that point you might as well get ball screws from Grainger.

Re: 3 axis router build

Posted: Fri Feb 01, 2013 4:06 pm

by David King

Eric,

The Enco stuff was in the sales flier at the bottom of page 51:

http://www.use-enco.com/CGI/INPDFF?PMKA ... &PMCTLG=01

Still no 3/8-16, only 3/8-12 but the 1/2 is $6 for a 3 foot length.

Re: 3 axis router build

Posted: Fri Feb 01, 2013 6:43 pm

by Eric Baack

cool, thanks! I'll have to check what shipping costs on that. 2 sticks of 6' will get me enough to do 2 screws on the x axis and enough for the other 2 axis as well

Re: 3 axis router build

Posted: Fri Feb 01, 2013 10:03 pm

by David King

You'll get 15% + free shipping today only if you buy $99 worth of stuff.

Promo Code: BIGSAVE and BIGSHIP. Those deals usually expire at 8:00 PM PST

Re: 3 axis router build

Posted: Sat Feb 02, 2013 12:01 am

by Eric Baack

meh, don't have the cash for it at the moment. Do they have promotions like that often?

Re: 3 axis router build

Posted: Sat Feb 02, 2013 1:17 am

by David King

These sales come 4-6 times a year. They always have a free ground shipping deal but it rarely stacks.

I keep a shop list and add what I need to the cart through the months so that I'm ready to pull the trigger when the sale comes around.

I get all my carbide from them so that adds up pretty quick. I get my truss rods from them as well (drill rod). Over time as you accumulate tooling it gets harder to make a shopping list and keep track of that you already own, what's sharp and what's dull etc.

Re: 3 axis router build

Posted: Sun Feb 03, 2013 11:01 pm

by Eric Baack

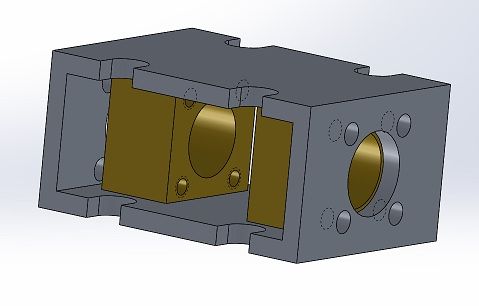

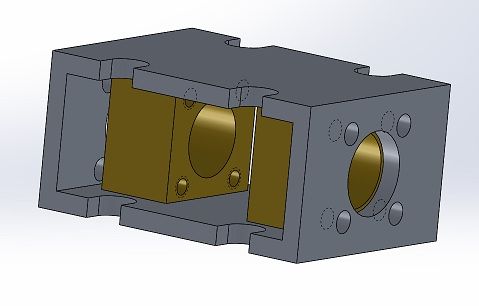

I'm thinking something more like this for an anti-backlash assembly. There would be a spring between the square nuts inside of the extrusion. One nut is bolted to the extrusion, the other one is used to put compression on the spring

Re: 3 axis router build

Posted: Sun Feb 10, 2013 10:38 pm

by Eric Baack

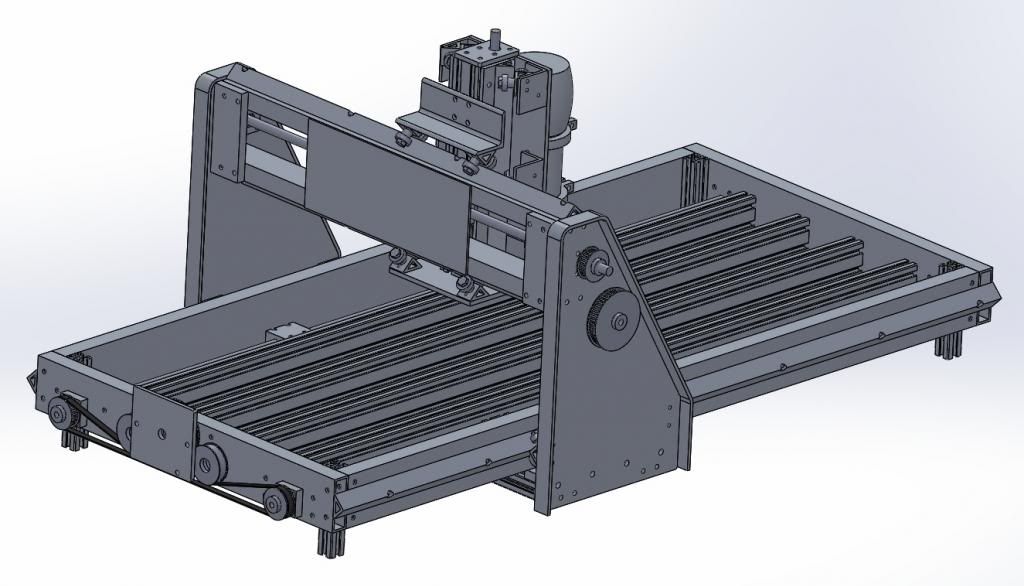

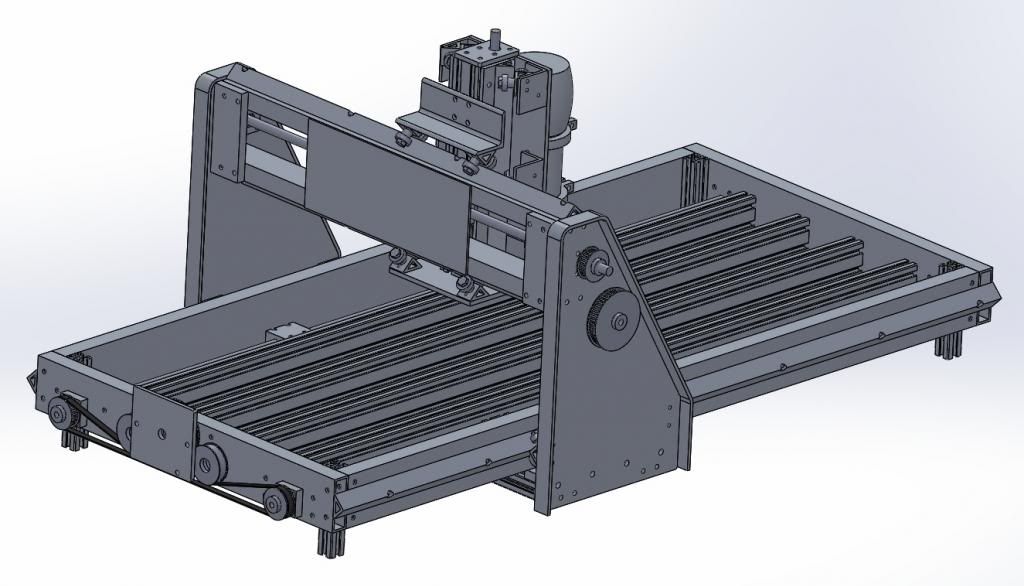

going to change some of the extrusion to rectangle tube instead of the spendy 8020. I'll make some inserts for the ends of the tubes so I can bolt them together and then add some gusset plates for strength. I'm also planning to add some outer webbing on the gantry side plates to strengthen those as well.

Re: 3 axis router build

Posted: Thu Feb 14, 2013 10:01 am

by Eric Baack

I rough cut the tube end caps today. those will tie the joints together. I will likely add some gussets after I have it all together. most of the bearing housings are cut and have pilot holes drilled. I'm going to make a fixture to bore out the pockets for the bearings with the lathe at work. hopefully I can pick up the extrusion for a decent price. maybe the scrap yard will have what I need. going to use 25-8670 for the bearing rails (gusseted angle extrusion)

Re: 3 axis router build

Posted: Thu Feb 14, 2013 1:25 pm

by David King

Eric,

Enco has another sale on through tomorrow, 10% off with no minimums. LOVETEN is your code. It might stack with this month's free shipping from $49 code LVHVS.

Re: 3 axis router build

Posted: Sat Feb 16, 2013 2:21 pm

by Eric Baack

ordered my 8020 gusseted angle extrusions last night

I just need some M8 x 22 screws and some standoffs to put the bearings together.

Re: 3 axis router build

Posted: Sat Feb 16, 2013 4:47 pm

by Louie Atienza

Eric, nice design and good luck! As to the AB nuts, you can buy them relatively inexpensively from DumpsterCNC.com, and I use them on two of my machines. I have one machine running with the same AB nuts I bought almost 4 years ago and the threads still look brand new.

Also, I would suggest using multi-start ACME screw, at least 2-start. You'll find that single-start screws will offer you middling performance, especially with the relatively high feedrates reqired to machine wood with high-RPM spindles. This has to do partially with the stepper's nature to lose torque as speed increases, and the larger the stepper you use, the faster that torque drops.

David, if the leadscrews are slightly preloaded axially, as long as everything is aligned well smaller leadscrews are fine; I used 1/2" on my machine. Smaller diameter leadscrews will whip at higher speeds and teh finer teh pitch, the faster the screw will need to spin, which is one more argument for multi-start leadscrews.

Re: 3 axis router build

Posted: Sat Feb 16, 2013 9:04 pm

by Eric Baack

I'm planning to step up the speed with pulleys on the X and Y axis. It will effectively make it like a 2 start screw as far as what the stepper sees.

If I need to upgrade it to a 2 or 5 start then I can do that in the future. I do think I'll still make my own AB nuts. I can make them for a bit less then the cost of the dumpsterCNC setup.

Re: 3 axis router build

Posted: Mon Feb 18, 2013 12:08 pm

by Louie Atienza

I've seen a few builds that use a spring mechanism as you shown, with not too favorable results. A solution I've seen that's also on some commercial machines would be to tension two leadnuts with belleville washers in between. Or you could possibly implement your design with belleville washers.

My only concerns for you as far as the single start screw is that you will need a lot higher feedrates than one would think for machining wood; I typically run between 75-250ipm depending on bit size, depth of cut, etc. Even gearing up your steppers, you still have to spin the screw at 750rpm just to get on the low side of the feedrate range. Trust me, your leadnuts, bearings, and screws are not going to like this after a half hour, let alone a few. Also consider the cost of the pulleys, belts, and idlers/tensioners, versus a stepper mount and motor coupling which by the way would be far more ridgid and offer less backlash. Ask me how I know...

Re: 3 axis router build

Posted: Mon Feb 18, 2013 12:25 pm

by Eric Baack

I'd still need the pulleys or go with a pair of steppers for the X axis to run the dual lead screw

Re: 3 axis router build

Posted: Mon Feb 18, 2013 12:51 pm

by Louie Atienza

Eric Baack wrote:I'd still need the pulleys or go with a pair of steppers for the X axis to run the dual lead screw

That I suppose would be unavoidable... I built my first and second machine using exactly the same idea of running two screws via one stepper with timing pulleys. I have to admit that the backlash was relatively low, but still there. "Clocking" the screws to each other were relatively simple, though if you use a setscrew-type hub it can be a pain. I found it easier to make the leadnut carrier adjustible. Clamp-type pulleys work great for this, though they are not cheap.

I did upgrade my system to run two steppers on the long axis, which does add to the cost (and you could easily modify yours in the future), but does eliminate some of the mechanical complexity, all of which contribute to backlash and positional error.