Small project

-

Alan Carruth

- Posts: 1305

- Joined: Sun Jan 15, 2012 1:11 pm

Re: Small project

Why not put a string on over the top, with a jury rigged peg instead of the neck? I think it's the balance of forces that comes into play here; at some break angle they balance out, so it's not the absolute force that matters. Use a dial gauge to read how far the bridge is pushed up or down with different bridge heights/break angles.

I'll note that you should do this with the box closed, so that would preclude using the test to figure out whether you can trim braces or not, unless you want to try Joe Curtin's trick. He noted that CA is designed to stick to protein. He sizes the linings and plate edges of violins he's experimenting with using weak hide glue, and lets it dry. Then he can put the plates on with CA for quick tests, since he's good at getting hide glue joints apart. When he's done the testing he wants to do he just has to remove the plates a last time, wash off the CA, and glue everything up with hide in the usual manner. The CA saves a lot of time in this sort of testing.

I'll note that you should do this with the box closed, so that would preclude using the test to figure out whether you can trim braces or not, unless you want to try Joe Curtin's trick. He noted that CA is designed to stick to protein. He sizes the linings and plate edges of violins he's experimenting with using weak hide glue, and lets it dry. Then he can put the plates on with CA for quick tests, since he's good at getting hide glue joints apart. When he's done the testing he wants to do he just has to remove the plates a last time, wash off the CA, and glue everything up with hide in the usual manner. The CA saves a lot of time in this sort of testing.

-

Kurt Temreto

- Posts: 34

- Joined: Thu Oct 28, 2021 2:28 am

Re: Small project

Out of curiosity I continued with the test setup yesterday, Alan.

Between the tail and neck block is a sturdy stick and longitudinally of the top there is a bar clamp. The body itself is also clamped to a sandpaper surface and is therefore difficult to move.

Several measurements were made with each time putting more tension on the bar clamp. Difficult to estimate how many kg the bar clamp gives, but no matter how I increased that pressure the deflection of the top remained 1 mm..

Between the tail and neck block is a sturdy stick and longitudinally of the top there is a bar clamp. The body itself is also clamped to a sandpaper surface and is therefore difficult to move.

Several measurements were made with each time putting more tension on the bar clamp. Difficult to estimate how many kg the bar clamp gives, but no matter how I increased that pressure the deflection of the top remained 1 mm..

-

Kurt Temreto

- Posts: 34

- Joined: Thu Oct 28, 2021 2:28 am

Re: Small project

And then.. I suddenly saw that old scale!

Getting 80 Kg is very easy, I definitely went higher in the test.

Even reaching the maximum (125 kg) is effortless..

Getting 80 Kg is very easy, I definitely went higher in the test.

Even reaching the maximum (125 kg) is effortless..

-

Kurt Temreto

- Posts: 34

- Joined: Thu Oct 28, 2021 2:28 am

Re: Small project

Measure neck angle:

For certain reasons, I want a detachable neck with this one.

First off, I don't like truss rod covers, so the truss rod will be accessible through the heel of the neck.

Second, finishing a guitar is much easier when the neck and body are separate.

So, before the box closes, something has to be prepared..

And because of the f holes, the access to the bolt is visible in the heel

For certain reasons, I want a detachable neck with this one.

First off, I don't like truss rod covers, so the truss rod will be accessible through the heel of the neck.

Second, finishing a guitar is much easier when the neck and body are separate.

So, before the box closes, something has to be prepared..

And because of the f holes, the access to the bolt is visible in the heel

- Peter Wilcox

- Posts: 1323

- Joined: Sun Jan 08, 2012 1:31 am

- Location: Northeastern California

Re: Small project

I must be misunderstanding something, but it looks like access to the bolt (to remove and install the neck) will be on the outside of the heel.

Maybe I can't fix it, but I can fix it so no one can fix it

-

Kurt Temreto

- Posts: 34

- Joined: Thu Oct 28, 2021 2:28 am

Re: Small project

You understand very well, Peter, the access to the (Allen head) bolt is on the outside of the heel..

-

Kurt Temreto

- Posts: 34

- Joined: Thu Oct 28, 2021 2:28 am

Re: Small project

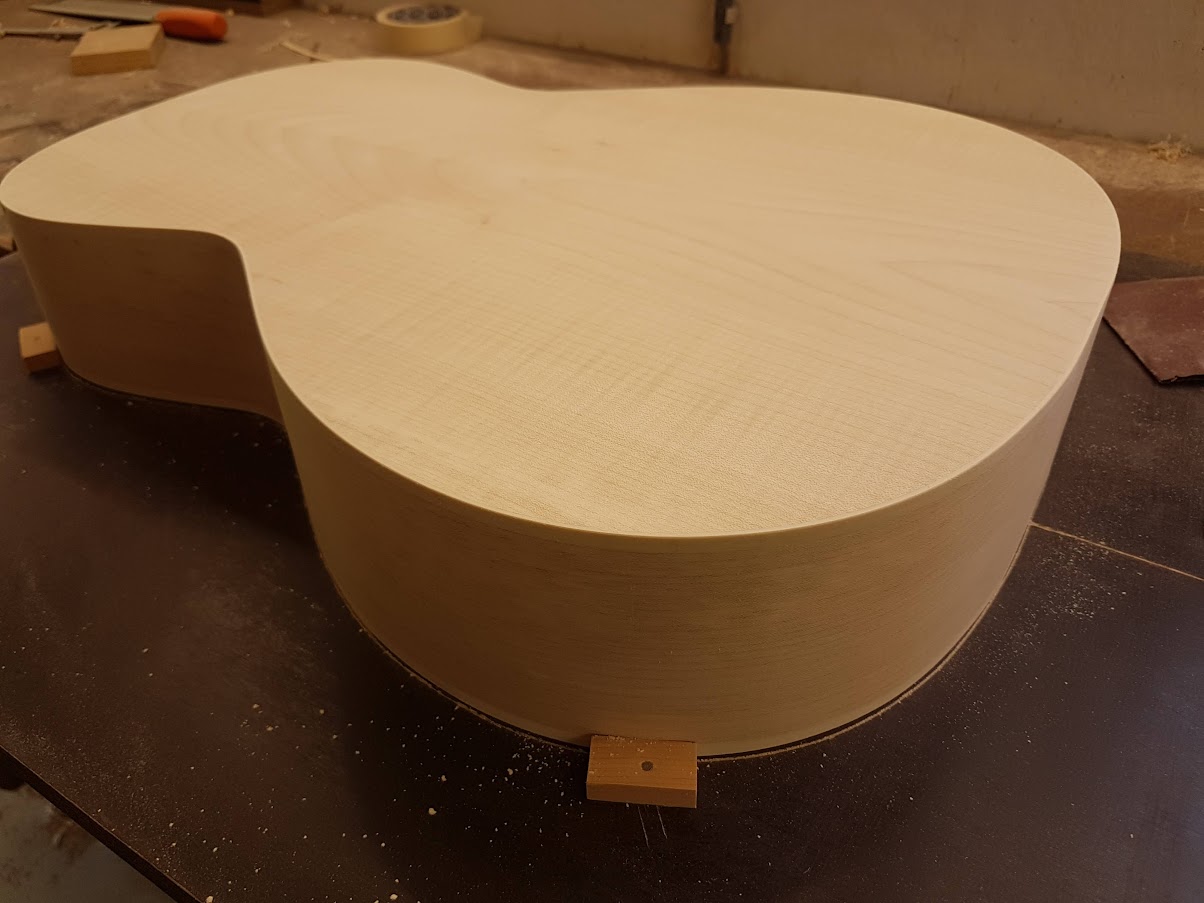

Box closed

And sides scraped flat, so the binding channels can be made

On previous projects I did it this way

But after applying a 'handle' this time I tried it like this:

It will stay that way; it works better and easier

Although I thought afterwards that it would work even better with this adjustment..

- Peter Wilcox

- Posts: 1323

- Joined: Sun Jan 08, 2012 1:31 am

- Location: Northeastern California

Re: Small project

Keep 'em coming, Kurt. I'm enjoying them, and getting ideas for when I get back to building my archtop bass - maintenance issues have gotten in the way for now.

Maybe I can't fix it, but I can fix it so no one can fix it

-

Kurt Temreto

- Posts: 34

- Joined: Thu Oct 28, 2021 2:28 am

Re: Small project

Looking forward to following your archtop bass project, Peter!

In the meantime, the binding has been installed

And a fretboard extension support has been made

In the meantime, the binding has been installed

And a fretboard extension support has been made

- Barry Daniels

- Posts: 3247

- Joined: Thu Jan 05, 2012 10:58 am

- Location: The Woodlands, Texas

Re: Small project

You are making good progress. What is the purpose of the tenon through the top? Not much to support it there.

MIMF Staff

-

Kurt Temreto

- Posts: 34

- Joined: Thu Oct 28, 2021 2:28 am

Re: Small project

The end of the fretboard is a few millimeters above the top and therefore needs to be supported, Barry, it seems more logical to me to do this through an extension at the neck than through a support on the top.

-

Kurt Temreto

- Posts: 34

- Joined: Thu Oct 28, 2021 2:28 am

Re: Small project

In the meantime found some time to put the truss rod in place..

-

Kurt Temreto

- Posts: 34

- Joined: Thu Oct 28, 2021 2:28 am

Re: Small project

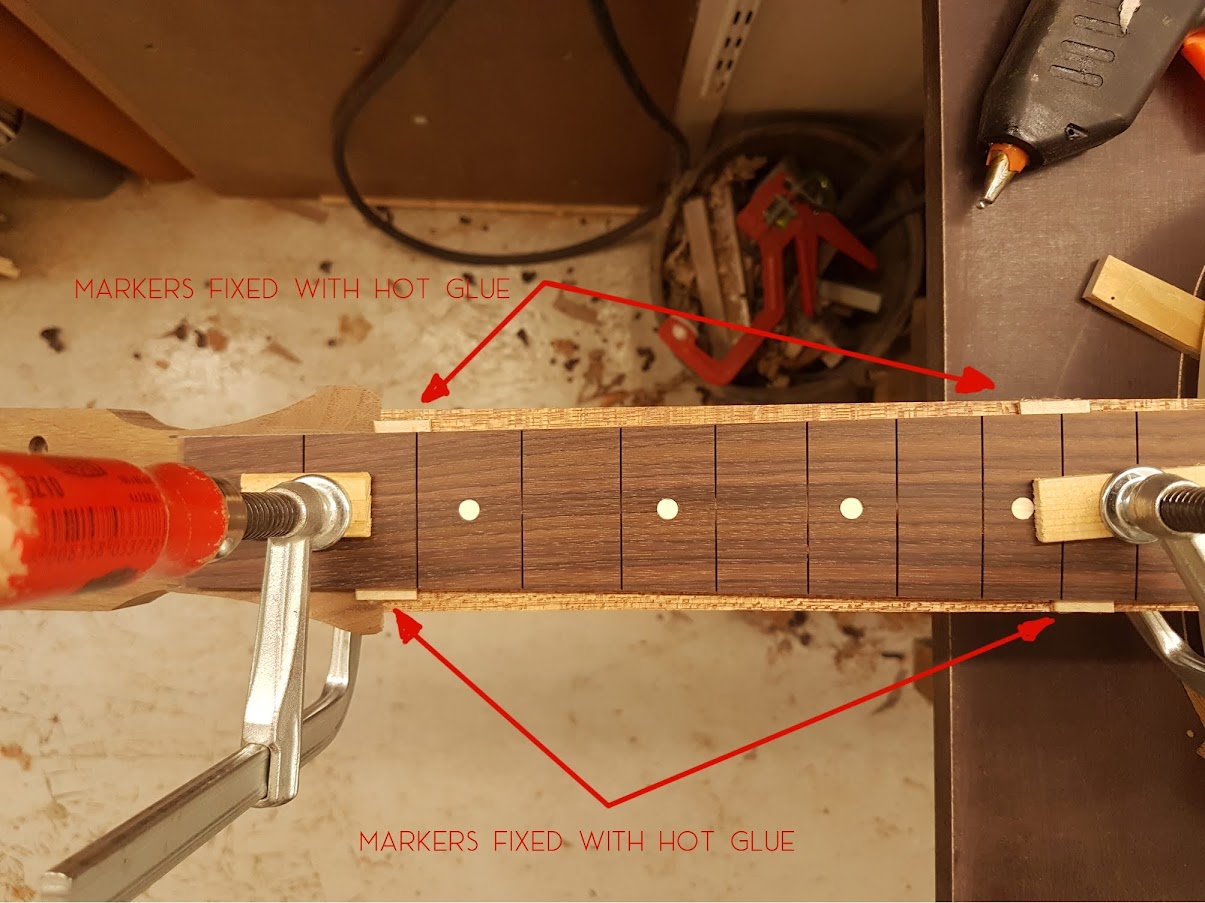

Preparing the fretboard

And because I want the fretboard inlay dots in the same color as the binding, I made them from a leftover binding

Align fretboard

and hold in place using a few small pieces of wood and hot glue

Gluing the fretboard in place is very easy that way.

- Barry Daniels

- Posts: 3247

- Joined: Thu Jan 05, 2012 10:58 am

- Location: The Woodlands, Texas

-

Kurt Temreto

- Posts: 34

- Joined: Thu Oct 28, 2021 2:28 am

Re: Small project

Gluing on the fretboard with a hot glue gun is probably not such a good idea, Barry, it's about the 'markers' that are glued with hot glue after the fretboard is aligned in the correct position

This way the fretboard can slide less easily during final gluing..

This way the fretboard can slide less easily during final gluing..

- Barry Daniels

- Posts: 3247

- Joined: Thu Jan 05, 2012 10:58 am

- Location: The Woodlands, Texas

Re: Small project

Wow, you had me worried there for a moment. I like to use positioning blocks also.

MIMF Staff

-

Kurt Temreto

- Posts: 34

- Joined: Thu Oct 28, 2021 2:28 am

Re: Small project

Took the time last weekend to shape the neck

-

Kurt Temreto

- Posts: 34

- Joined: Thu Oct 28, 2021 2:28 am

Re: Small project

After shaping the headstock

and installing the frets

Is it time to finish this machine (sigh)

When I look back at the guitars I've built so far (twenty or so), there isn't really a single one of which I am satisfied with the final result, and especially with the finish. However, I prepare very well, with a multitude of trials and experiments, but.. The instrument always looks best just before finishing. That's why I often thought about not applying a finish anymore.

But already at the start of this project I had the L-30 in mind as inspiration, in a black version..

And there you have a first obstacle: I did not expect that the plastic binding would also absorb dye (water-based, but probably also partly alcohol?). I'm not prepared to scrape the binding (I've never done this)..

- Peter Wilcox

- Posts: 1323

- Joined: Sun Jan 08, 2012 1:31 am

- Location: Northeastern California

Re: Small project

I found this to be most helpful:

https://www.youtube.com/watch?v=TNbsZsSabPs

I made scrapers out of old hacksaw blades. Most important is using your thumb as a guide while scraping.

https://www.youtube.com/watch?v=TNbsZsSabPs

I made scrapers out of old hacksaw blades. Most important is using your thumb as a guide while scraping.

Maybe I can't fix it, but I can fix it so no one can fix it

- Barry Daniels

- Posts: 3247

- Joined: Thu Jan 05, 2012 10:58 am

- Location: The Woodlands, Texas

Re: Small project

I don't mean to be a shill for StewMac, but their binding scraper is THE tool for doing this.

Scraper

And it is pretty easy to scrape plastic binding. I encourage you to give it a go.

Scraper

And it is pretty easy to scrape plastic binding. I encourage you to give it a go.

MIMF Staff