3 axis router build

-

Jamie Unden

- Posts: 144

- Joined: Mon Feb 20, 2012 5:25 pm

Re: 3 axis router build

The ones I find come with a 400Hz VFD and plug into 220V but they don't state what the required input power is. I'll have to email them when I get the money together.

-

David King

- Posts: 2690

- Joined: Sat Jan 07, 2012 10:01 pm

- Location: Portland, OR

- Contact:

Re: 3 axis router build

I think this is the one http://www.hitachi-america.us/supportin ... T3251X.pdf

-

Jamie Unden

- Posts: 144

- Joined: Mon Feb 20, 2012 5:25 pm

-

David King

- Posts: 2690

- Joined: Sat Jan 07, 2012 10:01 pm

- Location: Portland, OR

- Contact:

Re: 3 axis router build

That's probably overkill unless you have a very poor grade power coming.

One of these should work: http://www.ebay.com/itm/Square-D-3-KVA- ... 2a56d3b3e8

As you can see the shipping is more than the item. Look around locally and you may find that even a larger transformer saves you money over shipping in a smaller one. A larger transformer can also handle several motors at once if you can deliver enough watts.

One of these should work: http://www.ebay.com/itm/Square-D-3-KVA- ... 2a56d3b3e8

As you can see the shipping is more than the item. Look around locally and you may find that even a larger transformer saves you money over shipping in a smaller one. A larger transformer can also handle several motors at once if you can deliver enough watts.

-

Eric Baack

- Posts: 640

- Joined: Thu Dec 27, 2012 4:28 pm

Re: 3 axis router build

Another test piece, some more z-axis steps missed... evidently I need to really cut down the acceleration on my z-axis and maybe add some shielded cable to that motor. It has very distinct places where I'm running my finishing cuts that the z-axis moves a bit lower then on the previous cut path. I wonder if that axis needs a bit stronger motor. I"m hoping that it improves as the lead nut loosens on the screw just a bit.

-

Jamie Unden

- Posts: 144

- Joined: Mon Feb 20, 2012 5:25 pm

Re: 3 axis router build

I would vote for the stronger motor. I had the same problem. I broke one of my X axis motors and borrowed the big one from the Z axis temporarily and replaced it with a smaller motor and was slipping steps. Remember, the Z axis has to lift the carriage and router motor so it needs more oomph.Eric Baack wrote:Another test piece, some more z-axis steps missed... evidently I need to really cut down the acceleration on my z-axis and maybe add some shielded cable to that motor. It has very distinct places where I'm running my finishing cuts that the z-axis moves a bit lower then on the previous cut path. I wonder if that axis needs a bit stronger motor. I"m hoping that it improves as the lead nut loosens on the screw just a bit.

-

Eric Baack

- Posts: 640

- Joined: Thu Dec 27, 2012 4:28 pm

Re: 3 axis router build

my carriage isn't all that heavy but I'm looking at some other steppers I have. I will have to rebuild some brackets to do it. I could also throw a pulley on the lead screw and the stepper motor and give it a 2:1 speed reduction. I have room in the torque curve on the motor and would actually get into the higher torque section of the curve in doing so.

-

Eric Baack

- Posts: 640

- Joined: Thu Dec 27, 2012 4:28 pm

Re: 3 axis router build

I have a short HTD 15mm wide belt with a 34 tooth and 15 tooth pulley that would work with me just adding one new plate of 3" x 1/4" aluminum.

-

Eric Baack

- Posts: 640

- Joined: Thu Dec 27, 2012 4:28 pm

Re: 3 axis router build

I took the motor and lead screw out and the linear rail was binding pretty badly. It took a bit of force to raise and lower the router even with no lead screw in place. So I've loosened that up and I'll try and get things to line up a bit better. I'm still going to add the pulley reduction though. It will give a bit more margin.

-

Eric Baack

- Posts: 640

- Joined: Thu Dec 27, 2012 4:28 pm

-

David King

- Posts: 2690

- Joined: Sat Jan 07, 2012 10:01 pm

- Location: Portland, OR

- Contact:

Re: 3 axis router build

You could try a sash balance spring or a small gas strut.

-

Eric Baack

- Posts: 640

- Joined: Thu Dec 27, 2012 4:28 pm

Re: 3 axis router build

I don't think weight is an issue. The rails were binding BADLY. I think getting those to fit a bit better (may have to shim one) and adding the pulley will give me plenty of margin.

The motor was right in the 230 oz-inch range of it's torque curve and the z-axis sled is only around 15 lbs with the router installed.

The motor was right in the 230 oz-inch range of it's torque curve and the z-axis sled is only around 15 lbs with the router installed.

-

Eric Baack

- Posts: 640

- Joined: Thu Dec 27, 2012 4:28 pm

Re: 3 axis router build

so it moves smoothly with 3 of the bearings attached. The bracket for the 4th one has a bit of a bend to it. I'll try and straighten it out and see how it works then. I'm running a shielded cable for the z-axis now as well. The screw turns easily by hand now. It did not before.

-

Eric Baack

- Posts: 640

- Joined: Thu Dec 27, 2012 4:28 pm

Re: 3 axis router build

Got the bracket back on after using my precision adjustment tool (hammer) and it runs nice and smooth still  I have another chunk of pine glued up to test it out.

I have another chunk of pine glued up to test it out.

-

Eric Baack

- Posts: 640

- Joined: Thu Dec 27, 2012 4:28 pm

Re: 3 axis router build

It was working much better, though I will have to do some work on the neck joint design I think. It was much thinner then I anticipated. I need to measure and compare it to the model. then probably beef up the joint in the model.

Here are a couple of vids of it running

https://www.youtube.com/watch?v=LHzJDfceS-8

https://www.youtube.com/watch?v=eW-fXowECgo

Here are a couple of vids of it running

https://www.youtube.com/watch?v=LHzJDfceS-8

https://www.youtube.com/watch?v=eW-fXowECgo

-

Jamie Unden

- Posts: 144

- Joined: Mon Feb 20, 2012 5:25 pm

Re: 3 axis router build

Your videos are private so we can't watch them.

-

Eric Baack

- Posts: 640

- Joined: Thu Dec 27, 2012 4:28 pm

Re: 3 axis router build

ahh, yes, they should be public now

-

Eric Baack

- Posts: 640

- Joined: Thu Dec 27, 2012 4:28 pm

Re: 3 axis router build

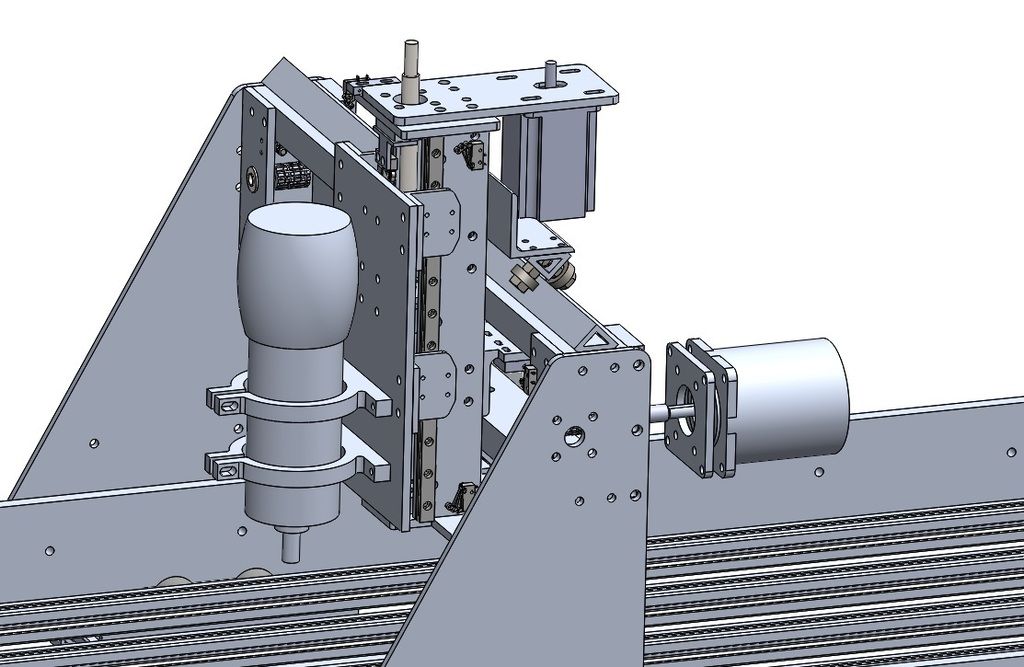

CNC is going to start a remodel before too long. I did get rid of the belts on the X axis and went with a pair of 1/2-10 5 start lead screws with a pair of nema 34 steppers running them, one being a slaved axis on the controller. The X motion runs great now. I had an issue with the belt drive on the X axis where my belts were walking over the flange of the pulley and getting all mangled up. So now that axis is smooth. I have a new set of actual linear bearings to replace my skate bearings. Once I have a bit more funds I'll replace my Y axis as well with some proper linear bearings and a lead screw. The side plates are going to change from 1/4" to 1/2" thick aluminum and I have welded up a steel gantry from 2" x 2" x 1/8" steel angle. It should stiffen the whole thing up significantly and get rid of the galling on my aluminum rails with the skate bearings.