Mini lathe: mega cheap

-

Jason Rodgers

- Posts: 1554

- Joined: Fri Jan 06, 2012 4:05 pm

- Location: Portland, OR

Re: Mini lathe: mega cheap

Huh, now that's a detail I was not aware of. This design came from the linked woodgears page above and it looked so simple and cool that I didn't even consider that 6-points is not typical. I shall also grant you an "I told you so," Clay, but I'm going to give it a try. My baton blanks are drilled out first for the shafts, just like pens, so there will be a pilot hole that ensures the chuck is centered. Actually, the more I think about it, the more I will likely need to make a mandrel like pen turners use. I have some time to figure it out.

-Ruining perfectly good wood, one day at a time.

-

Clay Schaeffer

- Posts: 1674

- Joined: Fri Jan 06, 2012 12:04 pm

Re: Mini lathe: mega cheap

I could be wrong, but the lathe you have the link to may also have a 4 spur chuck, even though it uses a six sided coupling nut. But give it a try, it may work fine.

-

Jason Rodgers

- Posts: 1554

- Joined: Fri Jan 06, 2012 4:05 pm

- Location: Portland, OR

Re: Mini lathe: mega cheap

Upon closer inspection, we might both be wrong: I think it's a 3-point spur. Of the six corners, three are taller, with three shorter in between. However you count em, they'll be sufficiently pokey and grab the wood.

-Ruining perfectly good wood, one day at a time.

-

Chuck Tweedy

- Posts: 1182

- Joined: Fri Jan 06, 2012 6:25 pm

- Location: San Diego, CA

Re: Mini lathe: mega cheap

Regardless of how many points it is supposed to have, you cut that piece quite cleanly!

(is that supposed to be irregardless??)

(is that supposed to be irregardless??)

Likes to drink Rosewood Juice

-

Jason Rodgers

- Posts: 1554

- Joined: Fri Jan 06, 2012 4:05 pm

- Location: Portland, OR

Re: Mini lathe: mega cheap

Irregardless ain't a word, Professor Tweedy. But yes, the spiky bits came out pretty well. Gotta love those Dremel cutoff wheels. They'll come apart on you in spectacular fashion if you nudge them fore or aft, but with a steady hand, they can make quick and relatively clean work of simple metal cutting tasks (with little heat buildup). I will take an extra minute to pull out the tool and set up a fresh wheel over the hacksaw any day.

And I came home to find a box of pulleys on my front step!

And I came home to find a box of pulleys on my front step!

-Ruining perfectly good wood, one day at a time.

- Dan Pennington

- Posts: 75

- Joined: Sat Jan 07, 2012 6:10 pm

- Location: Minneapolis, MN

Re: Mini lathe: mega cheap

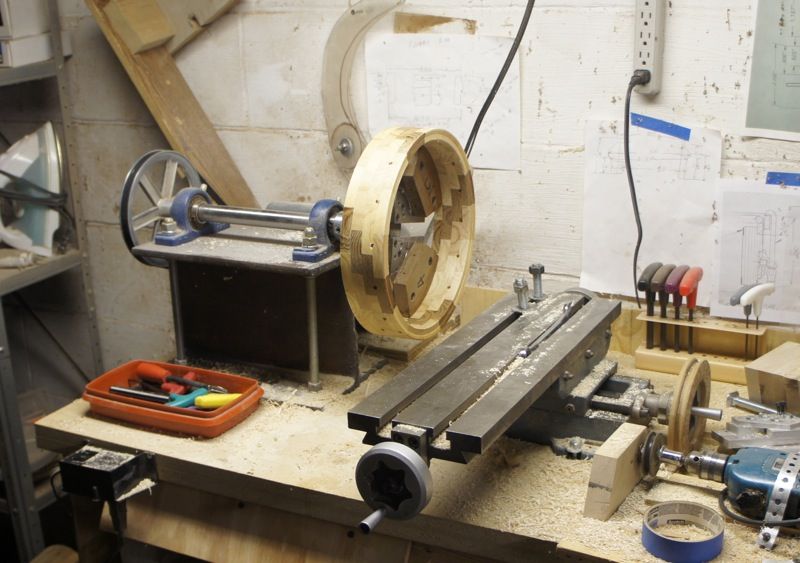

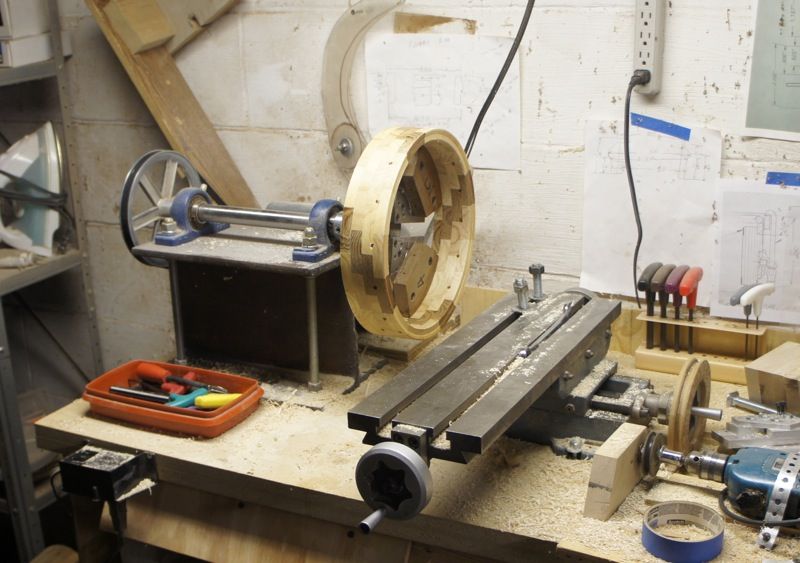

I made my own lathe for turning banjo rims. I had used regular wood lathes for half a dozen years and kept wearing them out. I can easily replace any part of it, so it will last as long as I do. I don't do spindles, so I don't need a tailstock. But if I did, I can figure out a way to do them.

Two $15 bearings are bolted to a hunk of large I beam - $40 from a scrap yard. A 2 horse motor, and pulleys from Farm-Fleet. Had the shaft custom made at a local machine shop for $80. The most expensive parts are the motor, the cross slide table and the chucks.

Two $15 bearings are bolted to a hunk of large I beam - $40 from a scrap yard. A 2 horse motor, and pulleys from Farm-Fleet. Had the shaft custom made at a local machine shop for $80. The most expensive parts are the motor, the cross slide table and the chucks.

-

Jason Rodgers

- Posts: 1554

- Joined: Fri Jan 06, 2012 4:05 pm

- Location: Portland, OR

Re: Mini lathe: mega cheap

Cool, Dan! I see that you even have a drill strapped to the table to power the x-axis cross feed. Built for what it needs to do. I like!

-Ruining perfectly good wood, one day at a time.

-

David King

- Posts: 2690

- Joined: Sat Jan 07, 2012 10:01 pm

- Location: Portland, OR

- Contact:

Re: Mini lathe: mega cheap

Having turned a couple of 15" banjo rims without a lathe I can honestly say I really appreciate this contraption. Routers and milling machines have their limits.

-

Jason Rodgers

- Posts: 1554

- Joined: Fri Jan 06, 2012 4:05 pm

- Location: Portland, OR

Re: Mini lathe: mega cheap

Here's a question about tool rests. I have an idea to span the turning gullet with a 1/2" piece of steel round rod, mounted in holes on the uprights. What sort of steel is used for tool rests? Does it matter? In the Lee Valley catalog on my coffee table, lathe tool rests are described as "hardened steel." At my local Ace, they have a selection of 12" stainless steel in various shapes, including 1/2" rods. Would this work? Does it matter what steel - tool vs. rest - is in contact, or just that it is sturdy and absorbs the shock of the tool on the work?

-Ruining perfectly good wood, one day at a time.

-

David King

- Posts: 2690

- Joined: Sat Jan 07, 2012 10:01 pm

- Location: Portland, OR

- Contact:

Re: Mini lathe: mega cheap

It shouldn't make the slightest difference what steel you use, 1018 CRS or A36 hot rolled would be easiest to bend into useful shapes and far cheaper than the stainless. You can buy steel at The Steel Yard for $.50-1.00 per lb. It does come in 12 and/or 20 foot lengths but they have lots of rems and a very reasonable cutting charge.

-

Jason Rodgers

- Posts: 1554

- Joined: Fri Jan 06, 2012 4:05 pm

- Location: Portland, OR

Re: Mini lathe: mega cheap

Hey, I know where that is. Good tip!

-Ruining perfectly good wood, one day at a time.

-

Clay Schaeffer

- Posts: 1674

- Joined: Fri Jan 06, 2012 12:04 pm

Re: Mini lathe: mega cheap

Hi Jason,

Your home made spur center inspired me to make one for one of my small lathes. (before I was using a screw type setup). I used a long bolt with the head cut off and a coupling nut . I rounded the coupling nut using the lathe and a file. Using the dremel worked a treat for cutting the spurs.

Your home made spur center inspired me to make one for one of my small lathes. (before I was using a screw type setup). I used a long bolt with the head cut off and a coupling nut . I rounded the coupling nut using the lathe and a file. Using the dremel worked a treat for cutting the spurs.

-

Jason Rodgers

- Posts: 1554

- Joined: Fri Jan 06, 2012 4:05 pm

- Location: Portland, OR

Re: Mini lathe: mega cheap

Yeah, pretty quick, huh? Having the ability to turn it right on the lathe sure is convenient, too. I'm still debating on how I want to finish the ends of my spindles. In the woodgears link, the guy just turned a centering point on both the drive end (with the spurred bolt) and a dead center on the tail shaft. If I used a severed bolt, as you did, I'd still have an unaltered threaded end to attach, say, some sort of mandrel like pen turners use. I have more time to think about it, though, as this weekend just got busy.

Show us a picture, Clay.

Show us a picture, Clay.

-Ruining perfectly good wood, one day at a time.

-

Jason Rodgers

- Posts: 1554

- Joined: Fri Jan 06, 2012 4:05 pm

- Location: Portland, OR

Re: Mini lathe: mega cheap

Ok, here's my next question: if I'm going to install my tool rest at a fixed height in relation to the centerline and distance from the work, where should it be? I did a little googling on proper tool rest positioning and got some general gouge/skew vs scraper height recommendations. Most of these were suggestions posted on other woodworking forums. One guy was making a bodger-type lathe and wanted to know, like me, where should I set-it-and-forget-it? The consensus seemed to be just below centerline, so a gouge resting level would contact the work at centerline.

This is technique jargon that is new to me. I would likely be using gouges, skews, and parting tools to turn these pear-shaped baton bulbs. I don't know about scrapers.

This is technique jargon that is new to me. I would likely be using gouges, skews, and parting tools to turn these pear-shaped baton bulbs. I don't know about scrapers.

-Ruining perfectly good wood, one day at a time.

-

David King

- Posts: 2690

- Joined: Sat Jan 07, 2012 10:01 pm

- Location: Portland, OR

- Contact:

Re: Mini lathe: mega cheap

Jason,

you need to make it adjustable height i'm thinking. Since it's going to eventually have interchangeable rests that can be rotated and locked, easy enough to accomplish this

you need to make it adjustable height i'm thinking. Since it's going to eventually have interchangeable rests that can be rotated and locked, easy enough to accomplish this

-

Clay Schaeffer

- Posts: 1674

- Joined: Fri Jan 06, 2012 12:04 pm

Re: Mini lathe: mega cheap

My (limited) understanding is that the difference between scrapers and shearing tools is the way the tool is sharpened and used. Scraping technique uses a relatively blunt edge and scrapes the wood to shape, where a shearing tool will act more like a plane or a chisel and shears the wood. A scraper would want to approach the work at close to 90 degrees and to make a shearing cut the tool would approach it at a slight angle. The tool rest should be adjusted accordingly.

-

Steve Senseney

- Posts: 673

- Joined: Fri Jan 06, 2012 2:45 pm

Re: Mini lathe: mega cheap

Make it adjustable.

For heavy work you will want good mass to avoid any vibration. For small work it will not need much mass.

For heavy work you will want good mass to avoid any vibration. For small work it will not need much mass.

-

Clay Schaeffer

- Posts: 1674

- Joined: Fri Jan 06, 2012 12:04 pm

Re: Mini lathe: mega cheap

I will try to post some pictures of the spur center and tailstock I cobbled together for a jewelers lathe I have. I am back to using a windows computer after going to a mac and then a linux OS so I don't know how well the pictures will turn out after resizing.

-

Clay Schaeffer

- Posts: 1674

- Joined: Fri Jan 06, 2012 12:04 pm

Re: Mini lathe: mega cheap

The pictures show the construction of the spur center. It is a threaded rod (sharpened on one end) with a coupling nut which has been rounded off and spurs cut with a dremel (as Jason did). The threaded rod passes through a brass tube that acts as a bushing which is then placed in the headstock. A wingnut secures the spur center in the headstock.

The tail stock Is just a block of wood with a machine screw threaded into the wood and a point sharpened on the end. It is secured to the lathe bed with a bolt and threaded insert.

With a little extra effort I'm sure a better looking rig could be made but this one works O.K.

The tail stock Is just a block of wood with a machine screw threaded into the wood and a point sharpened on the end. It is secured to the lathe bed with a bolt and threaded insert.

With a little extra effort I'm sure a better looking rig could be made but this one works O.K.

-

Jason Rodgers

- Posts: 1554

- Joined: Fri Jan 06, 2012 4:05 pm

- Location: Portland, OR

Re: Mini lathe: mega cheap

Nice work! That looks store bought.

Y'all have convinced me and I have begun work on an adjustable tool rest. It will be made of maple, attach to the uprights on either side of the turning gullet, and slide about 1/2"-3/4" up and down (so about 1/4"-3/8" above and below the center line). These baton bulbs are less than an inch in diameter at the widest, so I don't think it'll need to adjust in and out, just set about an inch from the center of spin. And if it doesn't work, I can try something else easily enough.

I don't know if this is considered heavy carving, but the last two batons I made used Osage and oak and it was difficult to remove material quickly with my less-than-perfect drill press setup. There were a few issues with this:

1. The material was drilled through and jammed on an 1/8" steel rod spindle, and anything more than the lightest touch with the gouge would stop it.

2. Working from the side, and at mid-torso height, it was difficult to present the tool at an appropriate angle.

3. Not being particularly confident in my setup, I didn't want to spin things over about 750rpm.

If this little lathe works as I hope it will, each of these obstacles will be eliminated.

Y'all have convinced me and I have begun work on an adjustable tool rest. It will be made of maple, attach to the uprights on either side of the turning gullet, and slide about 1/2"-3/4" up and down (so about 1/4"-3/8" above and below the center line). These baton bulbs are less than an inch in diameter at the widest, so I don't think it'll need to adjust in and out, just set about an inch from the center of spin. And if it doesn't work, I can try something else easily enough.

I don't know if this is considered heavy carving, but the last two batons I made used Osage and oak and it was difficult to remove material quickly with my less-than-perfect drill press setup. There were a few issues with this:

1. The material was drilled through and jammed on an 1/8" steel rod spindle, and anything more than the lightest touch with the gouge would stop it.

2. Working from the side, and at mid-torso height, it was difficult to present the tool at an appropriate angle.

3. Not being particularly confident in my setup, I didn't want to spin things over about 750rpm.

If this little lathe works as I hope it will, each of these obstacles will be eliminated.

-Ruining perfectly good wood, one day at a time.