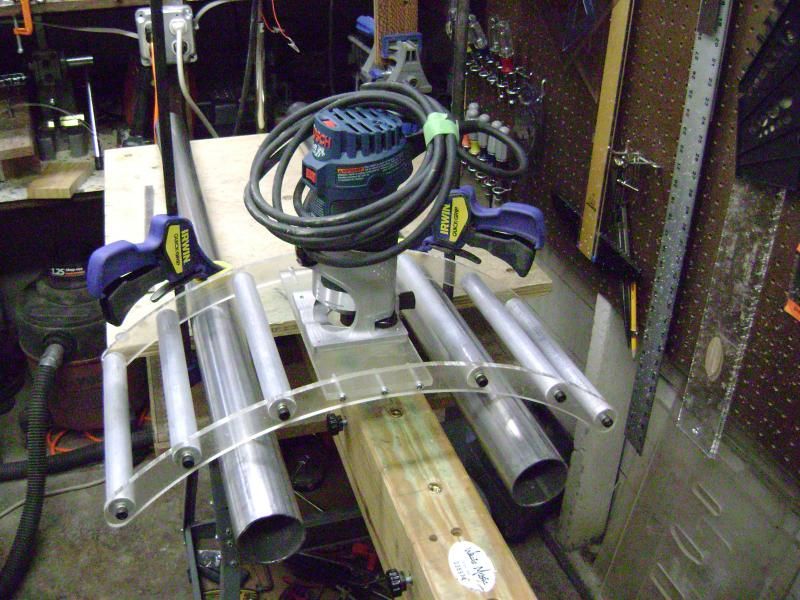

I didn't invent this concept but I love it so much I had to share it.

The jig was made mainly with scrap from around the workshop with a couple of pieces of PVC pipe and the Aluminium side supports costing about $10 from the hardware.

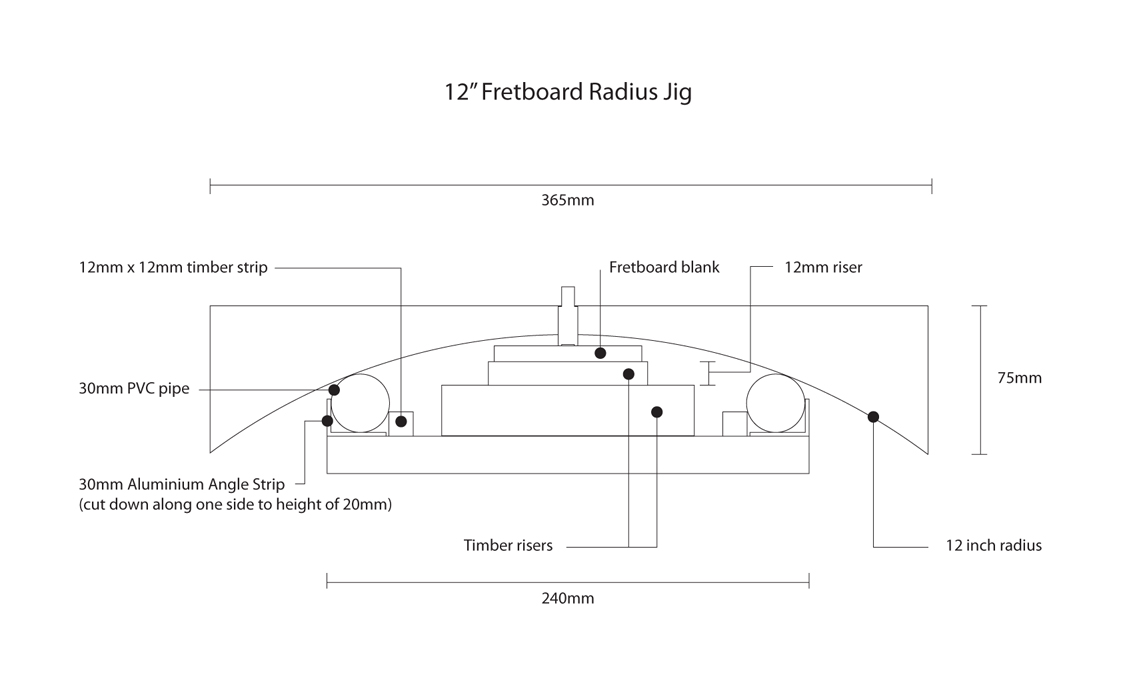

This is the set up for the 12 inch radius

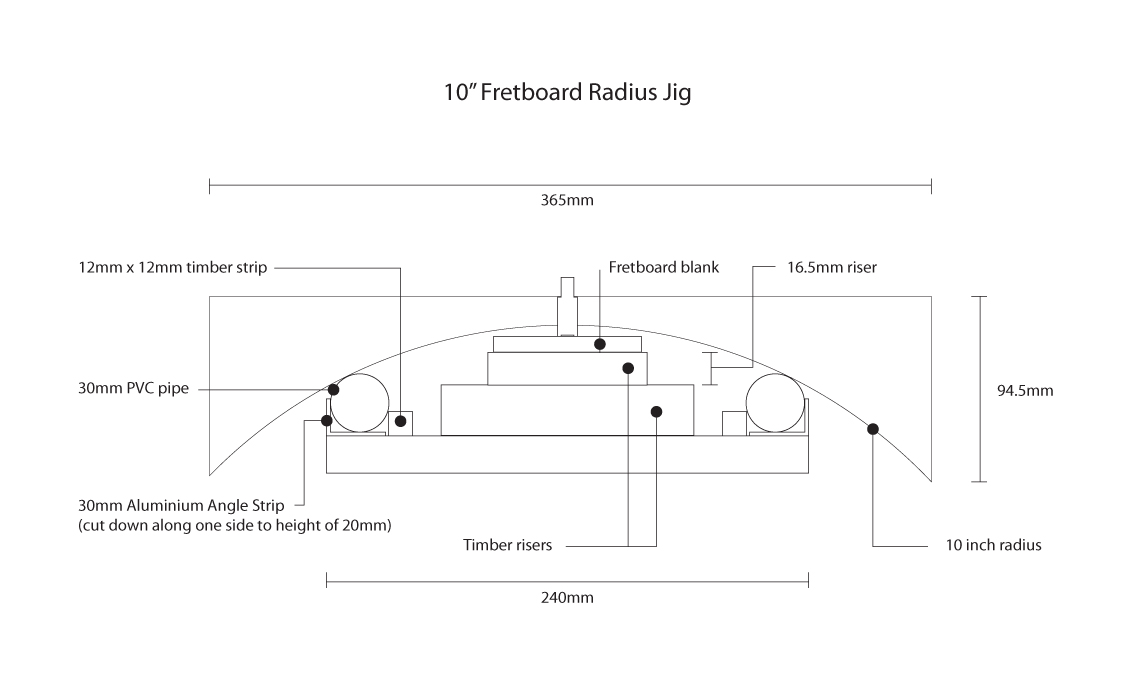

And if I want to do a 10" radius I just have to make a new box with the 10" radius on the bottom and raise one of the risers.