Couple of thoughts:

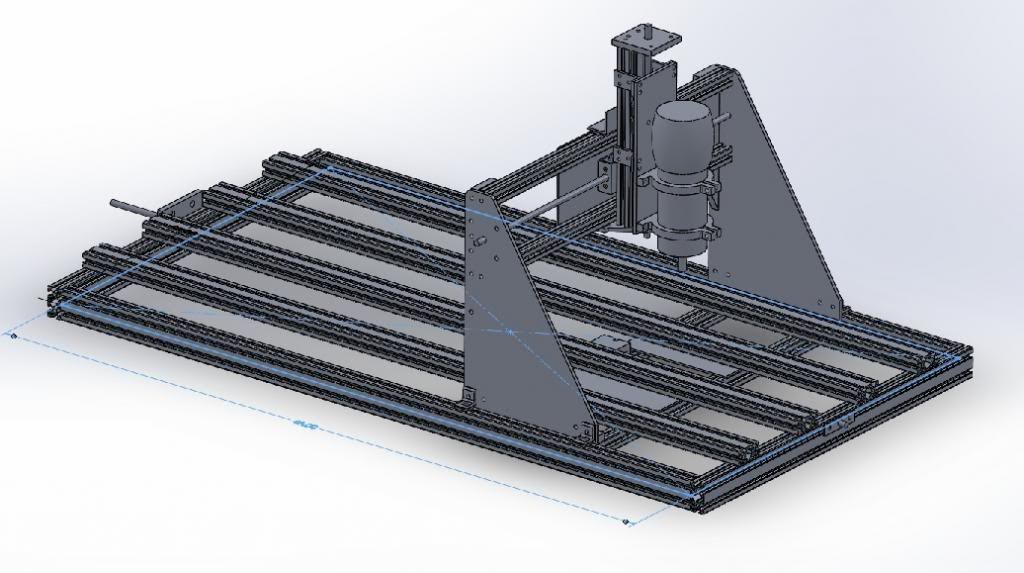

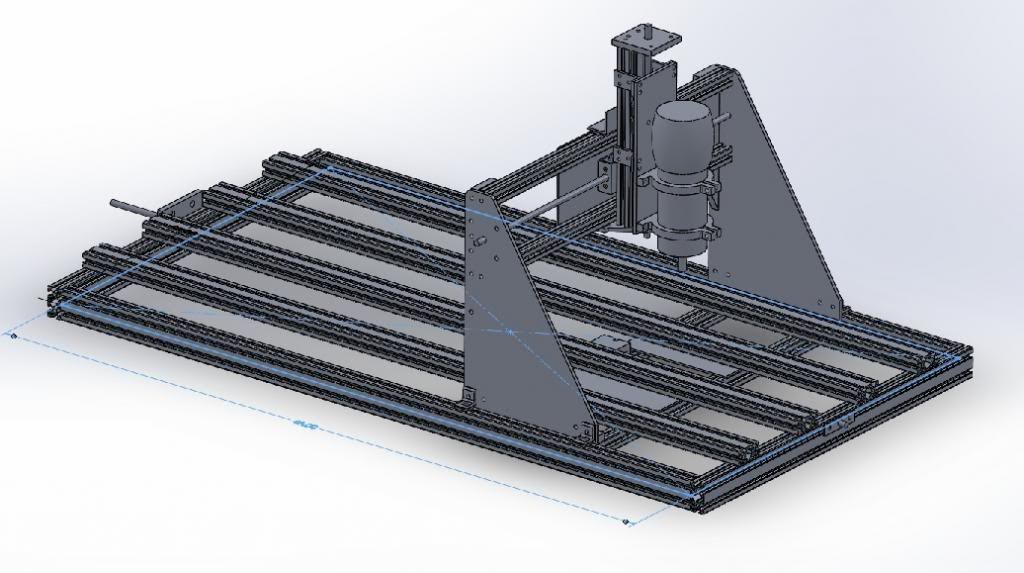

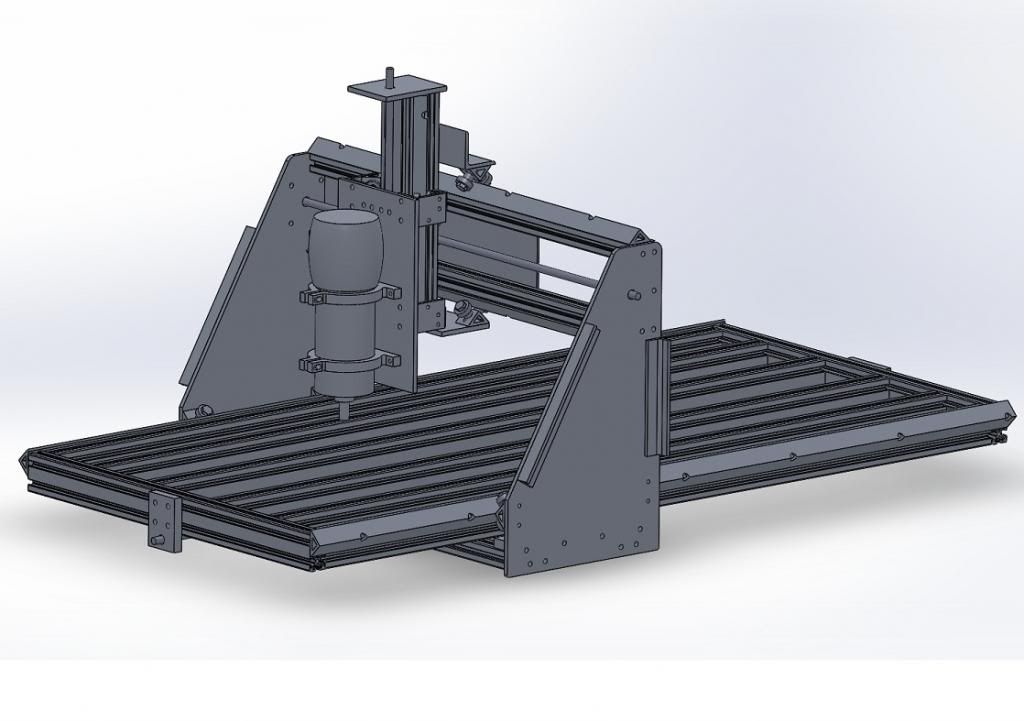

1) I'd extend those angles on the gantry uprights both up and down as much as you can. My gut is telling me that you'd get more stiffness benefit by moving them inboard a little and extending the lengths to overlap the Y-axis and your skate bearings than by keeping them as far apart as possible. You'll get a "hinge" type effect where they stop.

2) ACME rods need not be terribly expensive. At McMaster Carr you can by 6' of 3/8" rod for $30 (

http://www.mcmaster.com/#general-purpos ... ds/=l9vcx8 ). Regular threaded rod works horribly when you go CNC and your hands will probably get tired from spinning the hand wheels to get the thing to move. The issue is that stepper motors are strongest at low speed and with such a high thread pitch, you can't spin the screws fast enough to get any reasonable speeds (you'll want to be able to cut at 150ipm or better - I sometimes cut at 400ipm) Better yet would be a multi start rod but they're about twice as expensive as the single start rod. (toward the bottom of the page:

http://www.mcmaster.com/#acme-precision ... ws/=l9vauu )

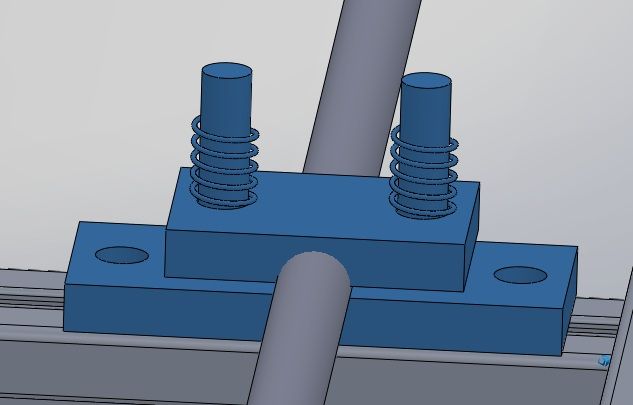

3) With the bearings you're using and the design, you might not be able to get away with a single lead screw at the center of your axis. There are plenty of machines that size and bigger that use a single screw but, they're very solidly built and use profile rails for bearings. Most designs I've seen like yours use two lead screws to move the gantry, one at each end, and are either synchronized with a belt or by slaving an axis motor in the control software. With a not-so-rigid design, you can get significant racking on your machine with the screw only at the center that can stop your machine dead or lead to really poor cuts.

4) For anti backlash nuts, a quick search on Google will yield a bunch of results on several methods of making your own. The two most popular are to either make a tap from your leadscrew or to cut your nut in half and heat form it to the screw. Or, just go to dumpster CNC and buy some:

http://www.dumpstercnc.com

And finally, just a comment that fixed gantry/moving table is the design used on the really high end routers - it's definitely the bomb setup if you have the shop space. There's also a guy on CNC zone that made a moving table type add on to his machine that moves the gantry and the add on table to extend his machines work envelope by like 4 feet or something. Very clever design!