My workshop has evolved over the years, but about 3 years ago I did a major overhaul and built it into its current configuration. I used some elements from its predecessors, and based on my experiences from those drew up a plan with a machine and bench layout that suits my work style and tooling, and made efficient use of the available space.

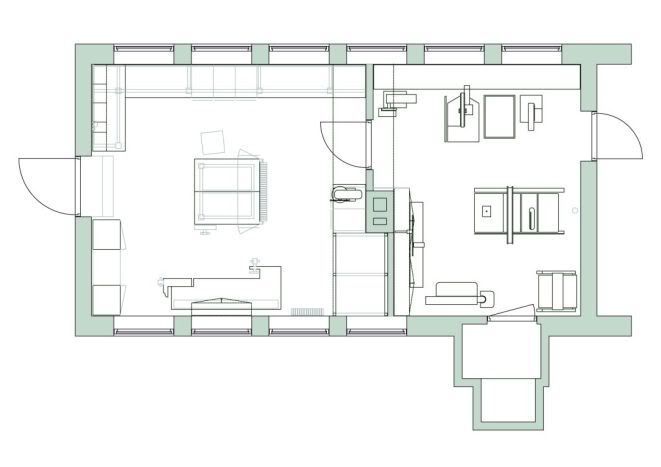

The concept is one “clean” bench / assembly room, and one “dusty” machine / wood processing room (and now, the third room, for finishing). Actually there is one more, small room, connected to the machine room, which is where I keep my dust collector.

Here’s the plan

First, some snapshots from the bench room...

The main workbench. Whatever I’m working on is usually on the “island” bench, while plans, parts, jigs, glue-ups etc are kept on the bench along the wall. For one thing, I have better access that way, but it also eliminates the chance of tools dropping on it etc.

I sometimes work on different things on either side of the bench, as the large work surface allows it. The bench also acts as a clamp rack, and holds a cabinet with abrasives, sanding blocks etc. I also keep a large 230/115 V stepdown transformer, a shop vacuum, trash can etc under it, and the added weight makes it very stable.

A closer look at some of the stuff over the wall bench; all within easy reach from my usual position between the two benches.

This is my sharpening bench. I use water stones, hence the HPL countertop. The wall cabinets are for books, the little drawers for small parts and supplies.

I enjoy working with hand tools, and an ancient planing bench is great for some of those tasks. The clamshell type cabinet holds most of my bench planes and regular woodworking tools

I monitor and control RH closely

Wood storage

Bridge blanks, headplates etc

More storage; tuners, pickups, strap buttons and whatnot. I like to keep this stuff fairly well organized, so I don’t have to waste time looking for it.

Works in progress

Various routers, jigs etc

That was all in the bench room, here’s the machine room:

Two bandsaws (one 24”, the other 12”), in front of my stash of Honduras mahogany.

Table saw with home made router table, and drum sander in the background

Jointer and edge sander