Production rim makers generally use one of two methods for making rims - laminating thin strips of wood in a circular mold or gluing blocks of wood together and the cutting it round on a lathe. I chose to do block rims right from the beginning and I've stuck with it.

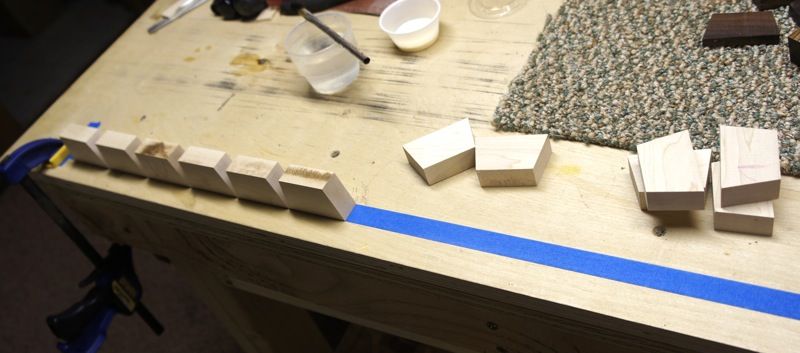

So, here's the start of Gary's rim. I used a table saw and a crosscut sled set at 11 1/4 deg. to cut 1 1/2 in. wide strips of 3/4 in. wood.

Using a technique borrowed from wood turners who make segmented bowls and vases. I laid down a strip of painters tape - sticky side up - and stuck 16 blocks end to end on the tape.

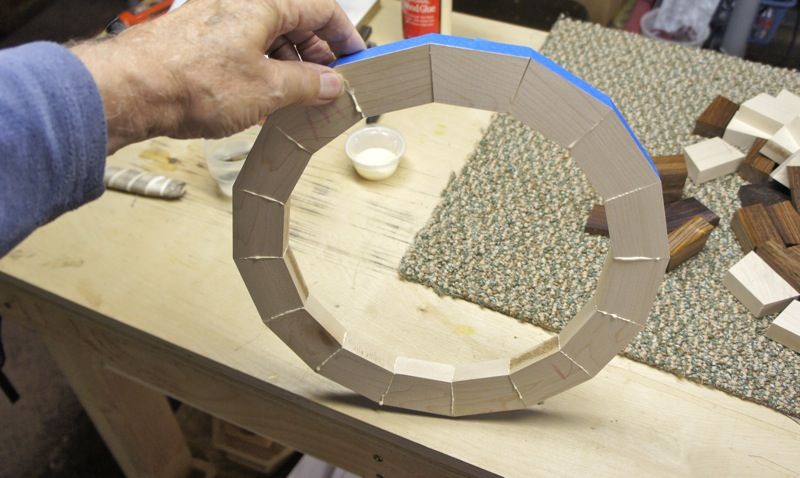

After brushing Titebond on all the joint surfaces, I rolled the tape up to make a ring.

And then used a large hose clamp to squeeze all the joints tight. Don't worry about the slight unevenness on the top surface. I'll run all the ring/layers thru my planer before I glue them together.

Here are five rings waiting for the glue to dry.